The fresh produce industry relies on fast-moving, high-efficiency supply chains to ensure perishable goods reach retailers in peak condition.

As sustainability continues to be a top priority, fresh produce companies are looking for more environmentally friendly pallet solutions.

Introducing Minor, Weir and Willis

Founded over 60 years ago, Minor, Weir and Willis (MWW) Ltd is one of the largest independent fresh produce businesses in the UK and Europe.

Founder Kewal Krishan Mehta began by importing fresh fruit, vegetables and salad, which reminded him of his home country, India.

The company prides itself on its focus on sustainability and responsible business, supporting communities at home and around the world and reinvesting profits to help provide a bright future for the company’s employees, suppliers and customers.

The goal: To find a smart, sustainable pallet solution that reflects their commitment to their customers and the planet.

The results: Reduced CO2 emissions, improved pallet durability, fewer disruptions, reduced costs, safer working conditions for staff

Our solution

Following previous discussions with their team, a conversation at the Festival of Fresh in 2024 sparked the start of our working relationship with Minor, Weir and Willis.

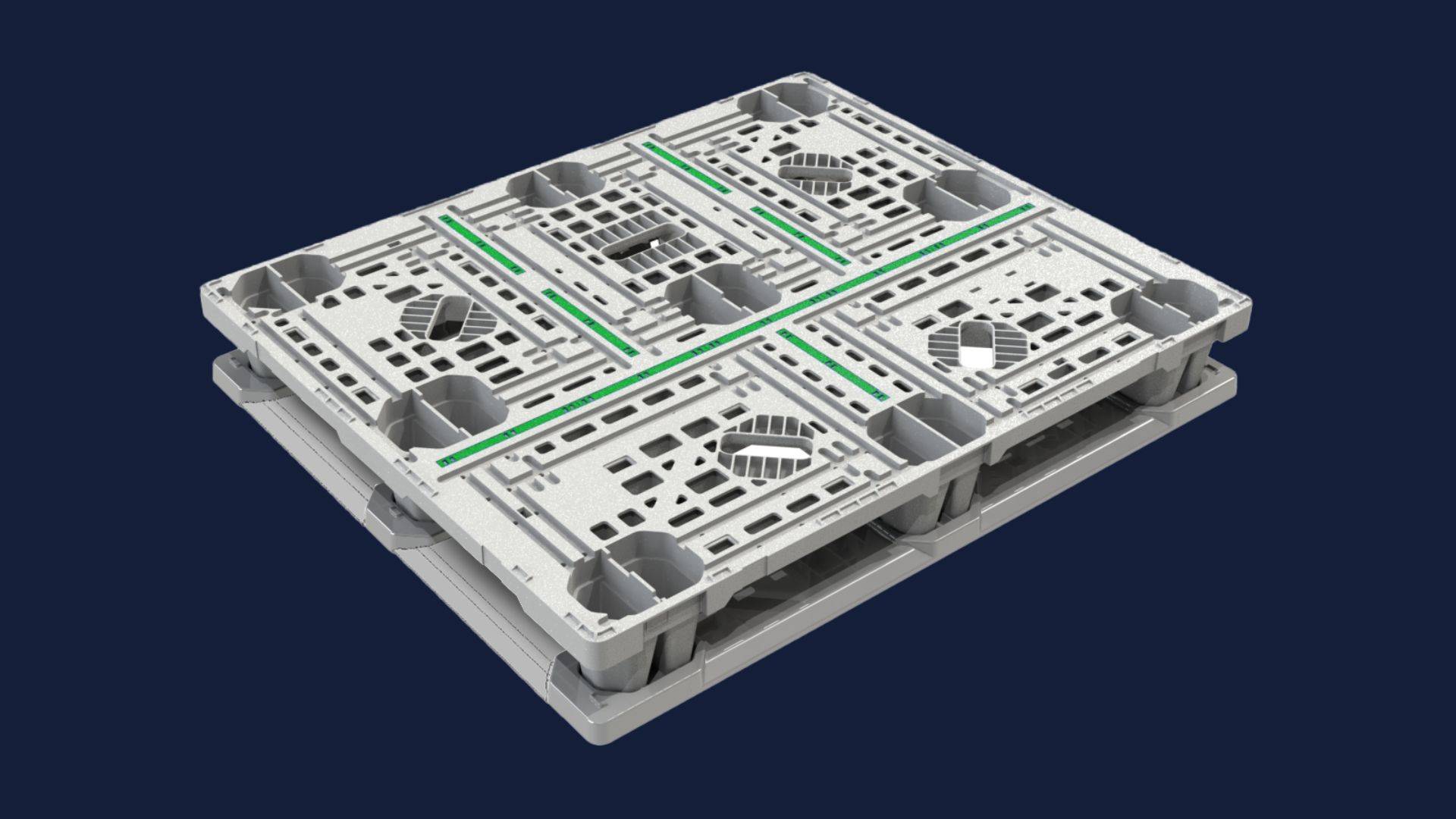

They realised that significant change starts with small implementations, deciding that Digipal’s Plastic Pallets would help them build a clearer, more efficient supply chain and support them in working towards their long-term sustainability goals.

Each of our Digipal Plastic Pallets is 10 kg lighter than a traditional wooden pallet which, when multiplied by their projected 80,000 pallets per year, results in an annual CO2 reduction of 5,900 kg.

Their switch is set to save close to 30 tonnes of emissions over the next five years.

The results

Although our relationship has only just begun, the MWW team is reaping the benefits of using our smart plastic pallets.

The warehouse and logistics teams have found that our plastic pallets are safer and more comfortable to handle, with no sharp edges and splinters. Plus, their consistency in weight and size makes them easier to transport, store and stack.

“To our partners at Digipal, thank you for helping us reimagine even the most everyday parts of our operation. And to others across the industry: if you’re still relying on wooden pallets, maybe it’s time to take another look.

Progress is possible, even on a pallet.”

Parveen Mehta, Operations Director, Minor, Weir and Willis

One early success was the simple steps it took to integrate Digipal Plastic Pallets into MWW’s supply chain.

You may think switching wooden pallets for plastics would cause disruption, but MWW is able to continue using the same administration, storage and transport processes, just with the added benefits that plastic pallets bring.

In fact, once we set to work, it only took three days for them to be able to start using our pallets.

Looking to the future

As of July 2025, we’re only seven months into our partnership with Minor, Weir and Willis. Over the next five years, our work is projected to achieve:

- ~29,280 kg of CO₂ saved through weight reduction

- Improved durability, fewer disruptions and lower replacement costs

- Safer working conditions

We’re proud that MWW has subscribed to our vision and we’re looking forward to continuing to build a more sustainable, efficient supply chain together.

Want to find out more about how our plastic pallets can help your business? Read more about them here.

Plus, see how sustainable your supply chain could become with our handy CO₂savings calculator.