Operations within the retail sector face many challenges.

With rising operational costs, shifting consumer demands, and increasing pressure for sustainability, logistics has never been more critical for businesses to reach their targets.

This report delves into the trends that are reshaping retail supply chains, offering insights and actionable strategies to help your business thrive.

With the latest innovations in technology making logistics cheaper, more efficient and more sustainable, now is the perfect time to explore how your business’s logistics could be improved.

We work with a huge range of businesses on improving their supply chain and logistics operations, and this has given us a unique insight into the latest trends that are having the most impact on the retail sector.

Here are the 9 biggest trends in retail logistics:

1. Use of Automation and AI

It might feel like every industry is finding new ways to utilise AI technology at the moment – and logistics is no different.

Quicker Decision Making

AI can help analyse and interpret huge volumes of data, giving retailers meaningful insights into where improvements within their operation can be made. Provided with enough data, AI could also help managers make quick decisions to resolve issues before they become a noticeable problem.

Limitless Insight

For drivers out on the road, fast insights with AI can help re-route drivers along quicker routes should traffic or accidents delay transport.

This doesn’t just mean on the road. AI can give immediate insights not just around transport, but it can also assist with stock management. Tracking products or packaging like roll cages and crates within a warehouse can help you optimise storage space and reduce retrieval times for faster order processing. Which leads us on to…

2. Omnichannel-Ready Supply Chains

Amazon Prime continues to be one of the strongest drivers of sales in the UK. Next-day and, on some occasions, same-day delivery is becoming the expectation for the entire retail industry, regardless of what they sell.

Customers are happy to pay more for speedy access to products and having a supply chain system that supports direct delivery to customers requires several systems:

Rapid stock management

Distributed warehouses

Efficient inter-warehouse transport

Organised last-mile delivery

By introducing or improving these four systems within your supply chain, it will be easier than ever to help your customers get their products quickly. However, you might find that even with the right planning in place, without sufficient oversight from those managing your supply chains it will be difficult to make sure products are where they need to be.

3. Integration of IoT Technology

Wireless tracking technology has improved drastically over the last decade and is only getting better as connectivity improves.

IoT (Internet of Things) helps operations managers get insight not just over the stock coming and going from their warehouse, but also where in the warehouse products should be. Access to these insights can drastically improve the efficiency both from management and between workers in warehouses.

This technology also allows for the complete digitisation of admin tasks like signing for deliveries which saves a significant amount of resources that would be taken up by printing.

Not having to print out manifests and stock levels doesn’t just cost time and money; it also helps businesses reduce their impact on the environment, something we’re seeing companies take more and more seriously.

4. Sustainability and sustainable logistics

As customers care more about where they spend their money, taking advantage of new technology to reduce emissions and minimise your impact on the environment is a powerful way to demonstrate your company’s commitment to corporate responsibility and sustainability.

Having a sustainable supply chain isn’t just about improving operational efficiency on the management side. New technologies like electric vehicles or the rise in renewable or efficient energy like solar panels or Combined Heating & Power (CHP) units has meant that becoming a greener retail business has never been easier.

Even better, often embracing these green technologies can help reduce costs in the long run.

This also includes paperless logistics. By digitising much of your operations, you can massively streamline data inputs.

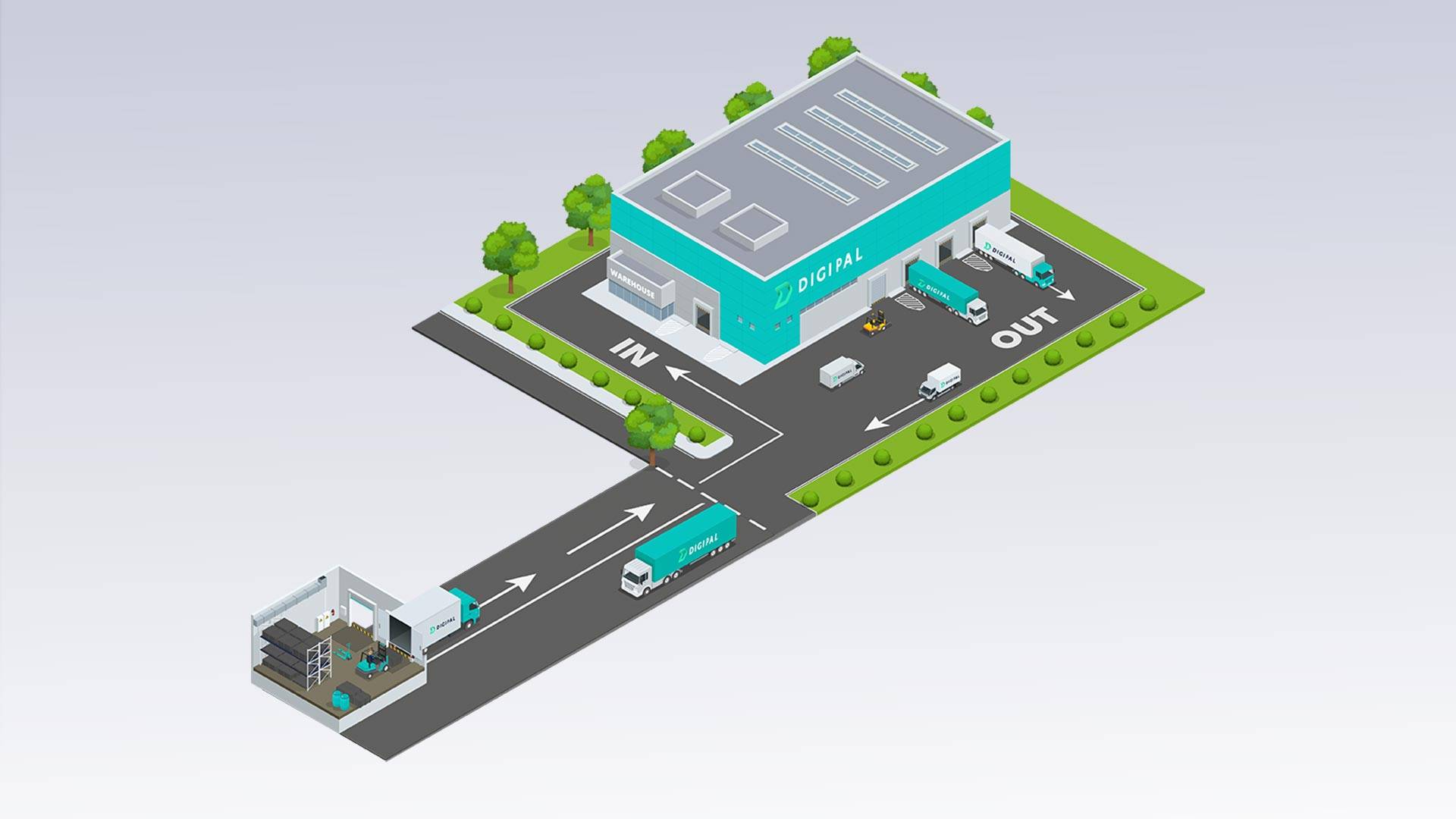

With asset tracking dashboards like Digipal’s DigiPortal, your head office can be instantly updated with insights across your entire supply chain without having to wait for store managers to fill out forms or delivery drivers to return to warehouses.

Digipal Partners with Carma

We have recently partnered with Carma, who carry out mangrove planting projects across Mteza, Creek and Kenya. Our customers are now directly contributing to their cause with every purchase translating to another tree being planted.

Restoring the mangrove biomes, which are rich in biodiversity, helps provide fishing grounds for local people. The restored forests will also help to stabilise coastlines, enabling them to act as a vital line of defence to protect the land and communities during tropical storms.

We couldn’t be happier to be adding Carma to the list of environmental partners Digipal works with, alongside The Woodland Trust, and helping contribute to their important cause.

5. Data-driven logistics

Sustainability isn’t the only thing affecting customers’ decision to buy. They are also looking for increased transparency between suppliers and customers.

Customers want more insights into day-to-day operations, and it’s not just about tracking their packages.

Consumers now care much more about the operations of the businesses they buy from, most notably the environmental impact of operations but also in the management of workers and drivers.

Retail businesses that seize the opportunity to turn the data collected on their own operations into actionable insights that can help improve efficiency, give back to the communities they operate in, and reduce their carbon footprint will have a big opportunity to draw in more customers.

6. New Innovations in Last Mile

Last mile delivery has seen some massive shakeups over the last few years. From freelance delivery drivers to new mobility solutions, the retail businesses that have found their footing in this shift are seeing real success.

But these benefits also come with costs.

More cities are introducing low-emission policies – such as London’s ULEZ scheme – making it harder to transport goods into urban areas. Investment into fleet EVs will no doubt save money in the long run, but many in the retail space don’t have the necessary capital to make that expense.

We’re sure that as fleets get older, retailers will likely be looking to EVs as their next replacement for vehicles.

And as the popularity of e-bikes and other single-person electric vehicles continues to take hold, smaller last-mile deliveries might only require a small, cheap to run, personal vehicle.

7. Impact of 5G (and 6G)

We expected 5G to have a huge impact on communication, and though it has improved connectivity across the country, as infrastructure continues to grow, demand will as well.

There have already been talks of moving ahead into 6G to better extend communication across wireless networks, but 5G has helped many retailers improve their tracking and communication all across the country and the wider world.

As access to the technology continues to grow, the supply chains that take advantage of 5G as it develops alongside new advancements in AI analytics will quickly find the best way to instigate operations that support customers, staff and stakeholders alike.

8. Forecasting and agility

In a post-COVID world, it has become clear that large crises, whether due to pandemics, environmental factors, or geopolitical developments, all can have a huge impact on businesses who aren’t prepared to handle big shifts.

By integrating data analytics into many of their processes , retailers can make sure their supply chains on both the supplier and consumer sides can handle sudden shifts in operations that are out of their control.

This agility won’t just help in the event of crises – by having clear processes for operations, plus staff with knowledge of what to do should processes be interrupted, you can make sure that operations can continue no matter what.

9. Embracing the circular economy

With plastic pallets becoming the more accepted solution compared to their less robust wooden counterparts, a new opportunity has opened up for suppliers across logistics operations.

Pooling your assets…

Pallet pooling involves leasing the use of pallets rather than the pallets themselves. This means the pallet supplier handles the storage and transport of empty pallets by using tracking technology to identify where pallets will be.

With the help of IoT technology, pallet pooling all but eliminates the need to secure space storing huge amounts of pallets whilst cutting down on the cost of transporting empty pallets back to warehouses.

This can save resources for both the pallet user and the pallet supplier.

A little about us…

Digipal are proud to be playing our part in a big shift in the supermarket supply chain – with a focus on reducing operational costs AND CO₂e. In the past 12 months we supported one of our retail clients in removing over 15,000kg of CO₂e from their operations just by simply switching from wooden pallets to Digipal Plastic Pallets.

Here at Digipal, we’re revolutionising retail supply chains. We design and manufacture the only rackable and nestable plastic pallets on the market, which are 25x more durable than wooden pallets.

The DigiPortal allows our customers a full oversight of their supply chain, letting them track anything they want with our range of tracking solutions.

We work with some of the UK’s biggest retailers helping them make their supply chains more efficient, more affordable and more sustainable. Whether you’re looking to purchase, rent, or join our pallet pooling program, Digipal has the solution to transform your logistics operations.